PHOENIX LININGS

Our Services

Rising Above

PHOENIX LININGS

Our Services

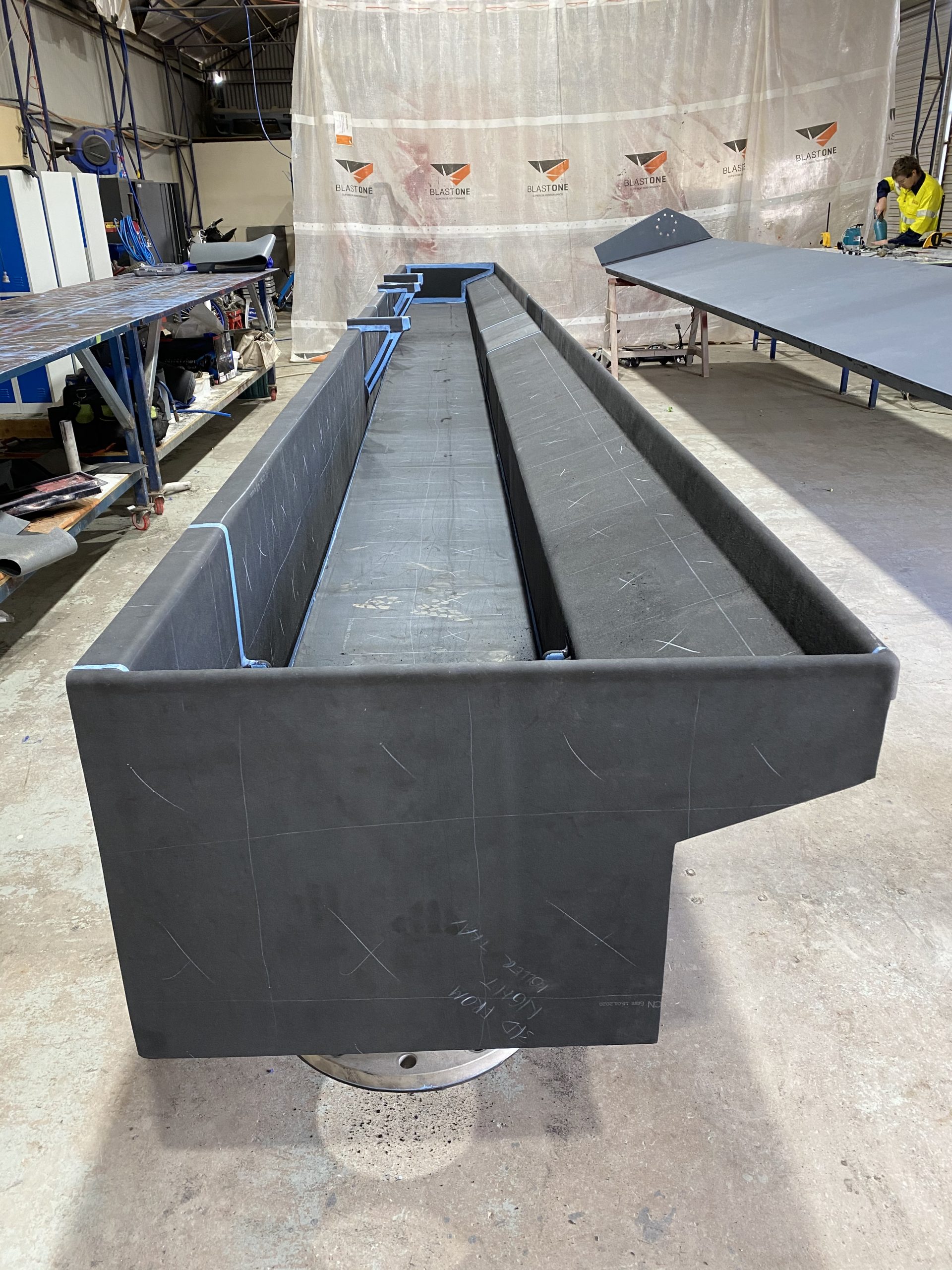

Large Tank & Vessel Lining

We have the specification knowledge, technicians, Equipment and product access to perform tank work projects safely and in timely and cost-effective manner anywhere in Australia no matter how remote the location or extreme the environment.

Rubber Lining

Phoenix Lining Services has established an effective team that are highly skilled in all types of industrial Rubber Lining. We can perform workshop based (including autoclave curing) as well as remote site-based tasks. We can specify and supply a highly specific rubber lining system in order to best protect your asset in-line with your budget.

Polyurea & Specialist Lining

Phoenix Lining Services through its preferred applicator status with Liquimix Construction Chemicals can specify and apply high performance polyurea systems to any number and variance of scopes. We have technical know-how and extensive dossier of case studies to ensure a long-lasting solution is put forward and delivered in-order to protect your critical asset.

Component Supply & Refurbishment

Phoenix Lining Services currently conducts component supply and refurbishment activities both from its Roxby Downs workshop as well as on its client mine sites. These activities range from the supply of one-off small components (spools, blanks, diverters etc) to scheduled rotable item refurbishment programs (chutes, hoppers, tanks, screens, agitator shafts etc).

Square Metres Of Lining Installed

Collective Years Experience

Rising Above Since

PHOENIX LININGS

Latest Review

Konrad Plant

Adelaide, Australia

“Got my Large Tank lined, the service was delivered with high quality equipment and performed in a timely manner making it very cost effective!”